In an increasingly interconnected world, reliable and efficient data cabling and networking infrastructure are vital for businesses and individuals alike. The United Kingdom, known for its technological advancements, has witnessed a remarkable evolution in data cabling and networking solutions. This article explores the significance of data cabling and networking in the UK, highlighting the key aspects and trends that shape the landscape.

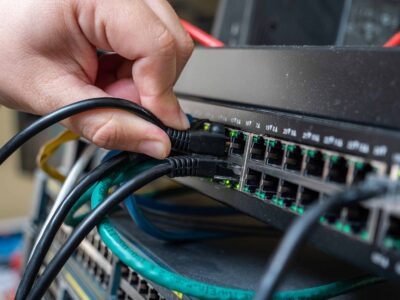

- The Importance of Data Cabling and Networking: Data cabling forms the backbone of any network infrastructure, allowing the transfer of information between devices, servers, and other network components. In the UK, where businesses heavily rely on digital systems, the importance of reliable and high-speed data cabling cannot be overstated. It enables seamless communication, efficient data sharing, and supports a wide range of applications, from cloud computing to video conferencing.

- Structured Cabling Systems: Structured cabling systems are the foundation of efficient networking in the UK. These systems provide a standardized approach to organizing and managing network infrastructure, encompassing cables, connectors, and related hardware. The UK follows international standards like ISO/IEC 11801 and TIA-568 for structured cabling, ensuring compatibility and interoperability across various network components. Such standardized cabling systems promote scalability, ease of maintenance, and cost-effectiveness.

- Copper and Fiber Optic Cabling: The UK has witnessed a shift from traditional copper cabling to fiber optic cabling due to its superior speed, bandwidth, and reliability. Fiber optic cables use light pulses to transmit data, enabling high-speed connectivity over longer distances without electromagnetic interference. The UK government has invested significantly in the deployment of fiber optic networks, aiming to achieve widespread coverage and support the growing demand for high-speed internet services.

- Network Infrastructure Upgrades: The UK has been actively upgrading its network infrastructure to meet the demands of emerging technologies. The advent of 5G, the Internet of Things (IoT), and cloud computing has necessitated improvements in network capacity, speed, and reliability. Investments in upgrading existing copper networks to fiber optic and the deployment of advanced networking technologies are key priorities for enhancing the country’s digital capabilities.

- Data Centers and Cloud Connectivity: Data centers play a crucial role in the UK’s networking landscape. These facilities house servers, storage systems, and networking equipment, providing the foundation for cloud computing services and hosting mission-critical applications. With the increasing adoption of cloud services, secure and high-speed connectivity between data centers and end-users has become paramount. The UK boasts a robust data center infrastructure, catering to the needs of businesses and individuals across various sectors.

- Network Security and Data Protection: As data networks become more interconnected, ensuring robust network security and data protection has become a top priority in the UK. Cybersecurity threats, such as data breaches and ransomware attacks, pose significant risks to businesses and individuals. Network infrastructure in the UK incorporates advanced security measures, including firewalls, encryption protocols, and intrusion detection systems, to safeguard sensitive information and prevent unauthorized access.

Choose JG Electrical for your networking needs and experience unparalleled expertise and reliability. From initial design to seamless installation, our team ensures your network infrastructure is optimized for efficiency and performance. Trust us to deliver cutting-edge solutions tailored to your requirements. Contact us today to elevate your networking capabilities with JG Electrical Services Ltd

FOR ANY ENQUIRIES, NO OBLIGATION QUOTE OR TO DISCUSS A PROJECT THEN

please click here to contact us